Classification of the Screw Press

Since the technological improvement and transition are so rapid, many machine types are only touched in the history among the following description on each screw press machine. The friction driven type of machine is already things of the past and following types, (1) and (4) through (11) , have less or extremely rare of production. The Vincent type, (6) , is servomotor driven in its driving type. Most of the screw press machines employed as forging are limited to (12) and (14) in the following

●Manual screw Press

●Friction Driven Type (Friction Screw Press)

-

(3)

General Type

-

(4)

Hasenclever Type(Modified model with only friction clutch portion)

-

(5)

Roll Driven Type (Roll driven instead of friction disc)

-

(6)

Vincent Type (Vertical Upset Type)

-

(7)

Double-Screw Type (A male screw has both CW thread and CCW thread together.for both thread, 2 female screw eguipped.)

-

(8)

Four disc Type(Two friction discs for slide down direction)

-

(9)

Clutch Type (Male screw and flywheel contact through clutch)

●Hydraulic Driven Type(Hydraulic motor driven flywheel)

●Direct Motor Driven Type(The type, a flywheel becoming a motor core)

●Servomotor Driven Type

-

(13)

Direct Axis Coupling Type (Ram speed, position and torque control method without flywheel)

-

(14)

)Energy Control Type (Flywheel revolution control method)

(Formerly, C-frame was used, however, most machines are now using straight side frame type.)

(1) Hand Screw Press

Vertical slide movement is made with the flywheel driven manually.

This is used for bending thin plate, etc., but is rare of new

production recently.

(2) Vice

A vise can be called exactly as screw press. The screw press that only has small screw angle and self-made locking (biting) status.

(3) Friction Screw Press

Most common and largest number of manufacturing result type.

Extremely simple structure. Though some of small machine models need hand operation, most machines are manufactured with electronic and pneumatic control system. Operation procedure becomes almost similar to ordinary mechanical press.

(4) Hasenclever Type Screw Press

This type has two friction wheels for ascending. Ideal method because wheel?fs peripheral speed transfers from low speed to high speed as the slide ascends, however, no actual result in manufacturing.

Originally designed by Hasenclever (then) in Germany, longest history holder in manufacturing of the screw press.

(5) Roll Driven Type Friction Screw Press

Instead of friction disc, two rolls are used to contact the flywheel and give driving power. Another model of the friction type.

Though there exists difficulty in friction heat radiation, a header part can be designed compact. The machine consists of two types: electromotive motor and hydraulic motor.

Weingarten (then) In Germany developed this, however, no manufacturing result lately.

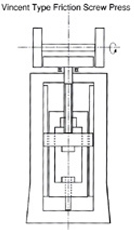

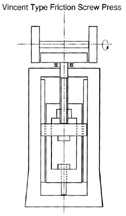

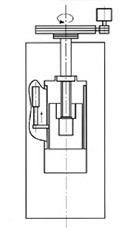

(6) Vincent Type Friction Screw Press (Vertical Upset Screw Press)

The type that mounts female screw into upper part of gantry typed slide and raising the female screw with male screw to ascend the slide for stamping. It has been well used for bolt forging based on the advantage of long stroke length possibility and adjustability for material protrusion and knockout structure. Up to now, most of the type had cone shape of friction wheel and flywheel to eliminate slippage from peripheral velocity difference since flywheel doesn?ft have up and downward movements. Recently, however, it became flat type to allow easy clutch lining manufacturing and replacement. Whole stamping pressure is absorbed within the slide and that reduces frame workload. It has unique structure to compare with other type of screw presses.

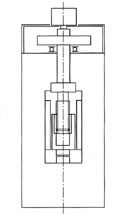

(7) Double-Screw Type Friction Screw Press

The type has a male screw with its upper and lower part threaded in CW and CCW respectively, and total two female screws are attached to the frame and the slide. During one rotation of the flywheel and the male screw, the slide moves two more times and this makes high-speed specification available as well as smaller friction disc diameter with compact machine header profile.

Enomoto Irons Co., Ltd. (Former company of current Enomoto Machine Co., Ltd.) developed the machine.

(8) Four-disc Type Friction Screw Press

In conventional friction type machine, the friction disc pushes the flywheel from one side resulted in increase of friction resistor because the increase of clutch operational pressure produces side pressure in screw bushes. Thus there was a limitation to shorten clutch start acceleration time. In this model, two friction discs are driven in opposite direction and sandwich the flywheel driven the clutch for descending to solve the above problems for the purpose of higher speed. The maximum ram speed reaches to the level of 1000mm/sec. Also, energy efficiency is getting better since less of friction loss from no side pressure on screw bush.

One more friction disc for slide ascending was also added making total of four discs. Enomoto Machine Co., Ltd. also designed the machine.

(9) Clutch Type Friction Screw Press

None of friction disc. Large capacity flywheel is always driven with motor and clutch installed between the flywheel and the male screw descends the slide. Ascending is made with cylinder (such as hydraulic) to pull the slide compulsorily when the clutch is released. This has the advantage of extremely high speed pressing with no need of accelerating period since the flywheel rotates at a constant speed from the beginning.

While the flywheel energy is consumed from the beginning of forging and has to cut the clutch off at the time of flywheel revolution down to a certain percentage by clutch cut-off signal. Or clutch will be cut off by the position of adjusted slide lower position. However, processing for clutch off timing is extremely short and the problem of excessive overload occurs due to only a slight deviance of clutch-off timing which actually brought a lot of machine breakdown by the overload, so some manufactures have to quit the production.

Another negative point is that flywheel energy can?ft be fully used for stamping operation as other screw press (Basically, the flywheel is unable to be stopped.)

(10) Hydraulic Driven Type Screw Press (Hydraulic Screw Press)

The type that the hydraulic motor directly drives flywheel. Energy control can be made with hydraulic oil flow control. Starting response is quite high because of no friction transmission mechanism.

Two major category: Ultra large machine that is impossible

Classification of the Screw Press for the machine with friction transmission mechanism and small machine that can cover several other machines?f capacity ranges with this model. Small machine furnishes with one unit of motor while large machine does with several motors coupled with gears of flywheel outer surface.

(11) Hydraulic Driven Twin-Screw Press

The type that furnishes with the two hydraulic motors driven flywheel set with a pair of screws in RH and LH. This system is robust for eccentric load. Foundation work costs low price because the machine will not rotate by itself since flywheel inertial moment is not generated at the time of pressure application. The basic type is a counter-blow type with upper and lower slides are installed but the type of only upper slide moves upward/downward is also available.

(12) Direct Motor Driven Type Screw Press

(Arc Starter Screw Press)

The type that the motor houses the flywheel itself as a part of motor core. Though consumption of electric power is large, no need of energy transmission mechanism made big manufacturing results for ultra large machine. Mid and small machines are also manufactured.

Objection exists for the replacement of motor which is a built-in exclusive use.

(13) Servomotor Driven Screw Press

(Speed, Position and Torque Control Method)

The type that the servomotor torque is transferred to screw axis directly or after amplified. The slide combined with the screw axis is controlled with forming speed, position and torque to have drawing operation for sheet metal. Forming capability is similar to hydraulic press machine. The machines ranging from several 10kN up to several 1000KN are produced. Two marketing possibility:

Mechanical press manufacturers develop it for their intention of controllability in forming condition. The other is hydraulic and pneumatic press manufacturers try to replace from current hydraulic and pneumatic mechanism. Attempting is made to put a general name, Servo-Press, summing up presses equipped with a servomotor including a mechanical press in which a servomotor is connected directly to a crank shaft.

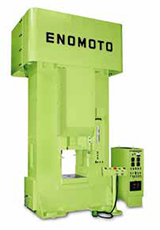

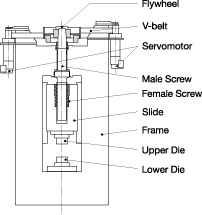

(14) Servomotor Driven Screw Press

(Flywheel Revolution Control Method)

The type that the servomotor controls the flywheel revolution and the slide position eliminating friction disc of the friction screw press. Detailed in latter part. Enomoto Machine Co., Ltd. developed it.