TIN TỨC

Nghiên cứu sản xuất Hợp Kim Ma-Nhê mới trên máy dập trục vis Enomoto

- 2003.09

<SUMMARY>

We have developed Automatic control system of Screw press machineモ to fabricate high-performance magnesium alloys with fine microstructures by the cyclical repeated plastic working (RPW) process, in the Japan government project for the technology transfer of the university seeds to industries, financially supported from 2002 to 2004. As a current result of this project, 3000kN Screw press machine has been already installed in the manufacturing plant of one of the above project members. He started to produce high-strengthened magnesium alloys specimens such as pipes, bars and plates via RPW process by using our press machine.

<DETAILS>

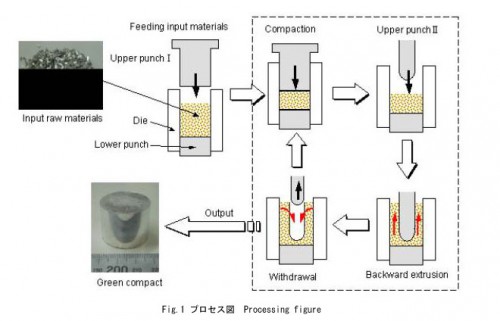

Professor Dr. K.Kondoh, RCAST (Research Center for Advanced Science and Technology), The University of Tokyo, had established the cyclical repeated plastic working (RPW) process, illustrated in  . In this process, two upper punch ?and ?are alternatively fed into the die set in the screw press machine with a high speed. The role of the punches is to consolidate the input raw materials (magnesium alloy coarse powder) to fabricate the green compact, and to progress the plastic deformation of the compact by the backward extrusion, respectively. In particular, the backward extrusion causes the refinement and mixing of the raw materials. That is, the RPW process by using the high-speed screw press is suitable to produce high-strengthened magnesium alloys. For example, as shown in

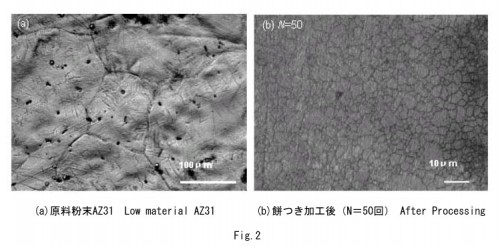

. In this process, two upper punch ?and ?are alternatively fed into the die set in the screw press machine with a high speed. The role of the punches is to consolidate the input raw materials (magnesium alloy coarse powder) to fabricate the green compact, and to progress the plastic deformation of the compact by the backward extrusion, respectively. In particular, the backward extrusion causes the refinement and mixing of the raw materials. That is, the RPW process by using the high-speed screw press is suitable to produce high-strengthened magnesium alloys. For example, as shown in , the grain size of the AZ31 magnesium alloy via the RPW process (N=50) is 3~5μm (b) by using 1000kN screw press

, the grain size of the AZ31 magnesium alloy via the RPW process (N=50) is 3~5μm (b) by using 1000kN screw press  (Fig.3 MOVIE)

(Fig.3 MOVIE)

The technology transfer project of the RPW process was started in 2002, to produce the advanced magnesium components in the industries, which was financially supported by METI, the Japan Government office for 3 years. The role of Enomoto machine in this project is to establish the automatic control system of the large-scaled screw press machine for the microstructure controls by RPW process.

We had already installed 3000kN Screw press machine for the RPW process, shown in  , in the manufacturing plant of Toyo Seiki Co., who is one of the above project members. They started to produce high-strengthened magnesium alloys specimens such as pipes, bars and plates via RPW process by using our press machine.

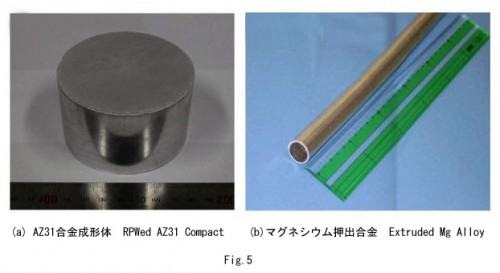

, in the manufacturing plant of Toyo Seiki Co., who is one of the above project members. They started to produce high-strengthened magnesium alloys specimens such as pipes, bars and plates via RPW process by using our press machine.  (a) indicates the AZ31 magnesium alloy green compact, having a diameter of 80mm and a length of 60mm, via the RPW process with 200 cycles. Fig.5(b) shows an example of the hot extruded AZ31 alloy specimens by employing the RPWed green compact. It reveals high strength with 350~400MPa of UTS.

(a) indicates the AZ31 magnesium alloy green compact, having a diameter of 80mm and a length of 60mm, via the RPW process with 200 cycles. Fig.5(b) shows an example of the hot extruded AZ31 alloy specimens by employing the RPWed green compact. It reveals high strength with 350~400MPa of UTS.

At the current state, the two research developments for technology issues are going; the 5000kN large-scaled screw press machine for RPW process and the application to the other university cooperation in foreign countries.

shows the appearance of 5000kN screw press equipment (a), having the automatic control system for RPW process. It serves the larger green compact with 145mm in a diameter (3kg). As the business strategy in foreign countries, we must develop the screw press machines for the plastic working of light metals such as magnesium and aluminum alloys, and import them to the material working companies, because automotive industries strongly require the light-weight components. First of all, we installed 1000kN screw press

shows the appearance of 5000kN screw press equipment (a), having the automatic control system for RPW process. It serves the larger green compact with 145mm in a diameter (3kg). As the business strategy in foreign countries, we must develop the screw press machines for the plastic working of light metals such as magnesium and aluminum alloys, and import them to the material working companies, because automotive industries strongly require the light-weight components. First of all, we installed 1000kN screw press  as a research equipment at Faculty of Engineering, Chulalongkorn university in Thailand this January 2003 under the collaboration partnership. They have been also developing the high strength light alloys by the RPW process and other hot workings such as forging or extrusion. Of course, our screw press machine is also useful for the research and development of the conventional hot working processes.

as a research equipment at Faculty of Engineering, Chulalongkorn university in Thailand this January 2003 under the collaboration partnership. They have been also developing the high strength light alloys by the RPW process and other hot workings such as forging or extrusion. Of course, our screw press machine is also useful for the research and development of the conventional hot working processes.

MOVIE show the Windows Media Player.